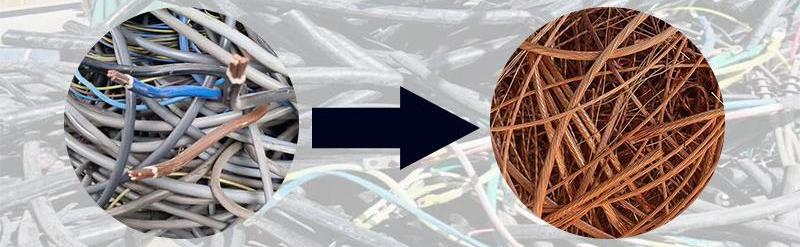

ST-009 wire stripping machine

- Category: Wire stripping machine

Small wire stripping machine is a precision equipment specially used for automatic stripping of wire insulation, which is widely used in electronic manufacturing, wire harness processing, maintenance and DIY fields. It has compact design and easy operation, suitable for processing small batches or fine wire operations.

Model

ST-009

Power

1.5KW

Net Weight

72KG

Wire Range

1.5-40mm

Dimensions

620*440*650mm

Structural composition

1. Cutter head system: High-strength cutter head, capable of cutting thick cables with a diameter of more than 50 mm, and supports layer-by-layer stripping of multiple layers of insulation(such as outer skin, shielding layer, and insulation layer).

2. Wire feeding mechanism: Rollers or clamps fix the cables to ensure stable wire feeding during stripping.

3. Adjustment device: supports flexible adjustment of wire diameter, stripping length, and stripping depth, and is suitable for wires of different specifications (such as 0.1–6 mm²).

4.Drive system: High-power motor, providing high-strength cutting power, suitable for hard materials such as metal armored wires.

Advantages

1. High productivity: greatly reduce the unit wire processing time and improve the overall efficiency of the factory.

2. Strong adaptability: can handle a variety of wires from ultra-fine coaxial cables to heavy armored cables.

3. High precision and stability: error ≤ 0.05 mm, ensuring the consistency of mass production.

4. Long life design: wear-resistant alloy blades and dust-proof structure are used, suitable for 24-hour continuous operation.

Purchase suggestions

1. Capacity requirements: Choose a single machine or multi-machine linkage solution based on the production scale.

2. Wire diameter range: Confirm the maximum/minimum wire diameter that the equipment is compatible with.

3. Energy consumption and maintenance: Large equipment needs to pay attention to power requirements (such as three-phase power).

Services

1. OEM and ODM customization available

2. Controllable delivery time

3. Ensured stable quality

4. Regular technical updates

5. Technical training sessions for operators

6. 24/7 customer service availability

After-sales Support

1. Provision of test videos before delivery

2. Video-guided installation

3. Free replacement parts

4. One-year warranty

5. Lifetime technical support

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Alice

Mobile:+86 15991605453

Tel:+86 15991605453

Whatsapp:8619991805031

Email:alice@strykermachinery.com

Add:Room 1002, Building 10, District 2, Duyong Village, Changxiang Street, Chang'an District, Xi'an, Shanxi Province